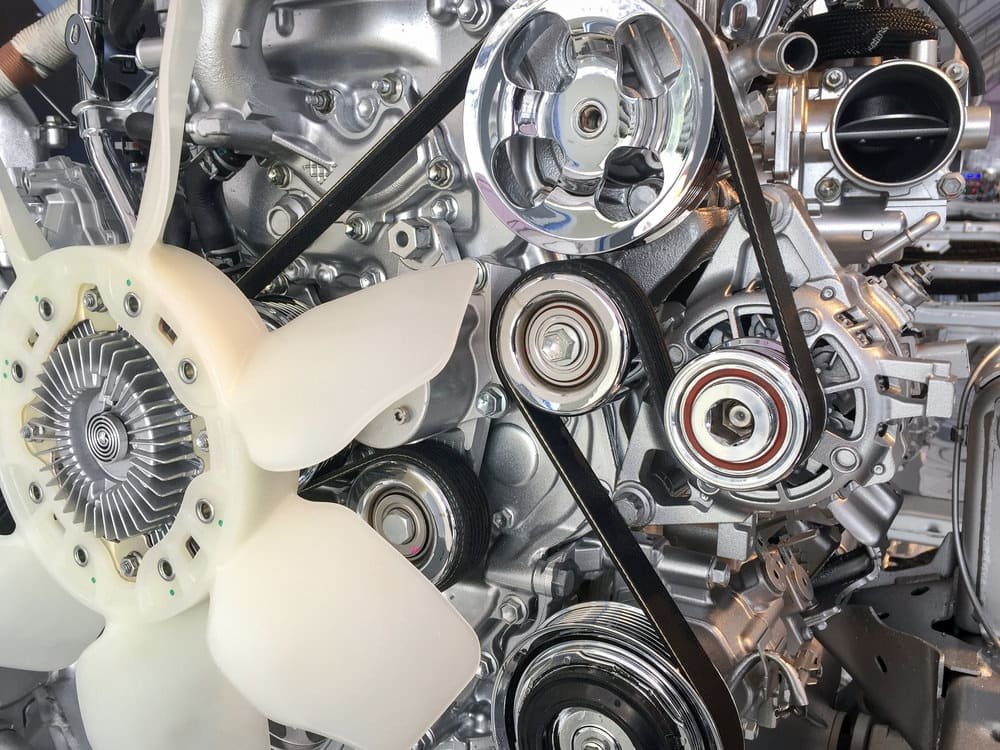

Drive belts are an essential component of a vehicle’s engine, playing a crucial role in the operation of various systems such as the alternator, power steering, air conditioning, and water pump. Over time, drive belts can wear out, crack, or break, leading to potential engine failure and costly repairs. Regular inspection and timely replacement of drive belts are vital to ensure the smooth operation of your vehicle. This guide will provide an in-depth look at drive belt replacement services, covering everything from the types of drive belts to the steps involved in their replacement.

Types of Drive Belts

1. Serpentine Belt

The serpentine belt is a single, continuous belt that snakes its way through multiple pulleys to power various engine components. It is the most common type of drive belt found in modern vehicles. The serpentine belt is designed to be durable and long-lasting, but it is not immune to wear and tear.

2. V-Belt

V-belts are older technology and are typically found in older vehicles. They are named for their V-shaped cross-section, which allows them to grip the pulleys more effectively. V-belts are usually used to power a single component, such as the alternator or water pump. Unlike serpentine belts, a vehicle may have multiple V-belts, each dedicated to a specific function.

3. Timing Belt

The timing belt is a critical component that synchronizes the rotation of the crankshaft and camshaft, ensuring that the engine’s valves open and close at the correct times. While not technically a drive belt, the timing belt is often discussed in the same context due to its importance and the need for regular replacement.

Signs That Your Drive Belt Needs Replacement

1. Squealing Noise

One of the most common signs of a worn-out drive belt is a high-pitched squealing noise, especially when starting the engine or turning the steering wheel. This noise is often caused by a loose or slipping belt.

2. Cracks or Fraying

Inspect the drive belt for visible signs of wear, such as cracks, fraying, or glazing. These are clear indicators that the belt is nearing the end of its lifespan and should be replaced.

3. Difficulty Steering

A failing serpentine belt can affect the power steering system, making it harder to turn the steering wheel. If you notice increased resistance when steering, it could be due to a worn-out drive belt.

4. Overheating Engine

The drive belt powers the water pump, which circulates coolant through the engine to prevent overheating. If the belt is damaged or broken, the water pump may not function correctly, leading to engine overheating.

5. Electrical Issues

The alternator, which charges the battery and powers the electrical system, is also driven by the serpentine belt. A failing belt can lead to dimming lights, a dead battery, or other electrical issues.

The Drive Belt Replacement Process

1. Initial Inspection

The first step in the drive belt replacement process is a thorough inspection. A certified technician will examine the belt for signs of wear, such as cracks, fraying, or glazing. They will also check the tension of the belt to ensure it is not too loose or too tight.

2. Removing the Old Belt

Once the technician has determined that the drive belt needs replacement, the next step is to remove the old belt. This process varies depending on the type of belt and the vehicle’s make and model. For serpentine belts, a belt tensioner tool is often used to release tension and allow the belt to be slipped off the pulleys. For V-belts, the process may involve loosening the alternator or other components to create enough slack to remove the belt.

3. Inspecting Pulleys and Tensioners

While the belt is off, it’s a good idea to inspect the pulleys and tensioners for any signs of wear or damage. Worn-out pulleys or a faulty tensioner can cause the new belt to wear out prematurely. If any issues are found, these components should be replaced as well.

4. Installing the New Belt

The new drive belt is then installed by routing it around the pulleys according to the vehicle’s belt routing diagram. For serpentine belts, the belt tensioner is again used to create enough slack to slip the belt onto the pulleys. The tensioner is then released, allowing the belt to tighten properly.

5. Testing the New Belt

After the new belt is installed, the technician will start the engine and check for proper operation. They will listen for any unusual noises and ensure that the belt is running smoothly without slipping. The technician may also check the belt tension one final time to ensure it is within the manufacturer’s specifications.

6. Final Inspection and Clean-Up

Once the new belt is confirmed to be functioning correctly, the technician will perform a final inspection to ensure everything is in order. Any tools or equipment used during the replacement process will be cleaned up, and the vehicle will be ready for the road.

Importance of Professional Drive Belt Replacement

1. Expertise and Experience

Professional technicians have the expertise and experience to correctly diagnose and replace drive belts. They are familiar with the specific requirements of different vehicle makes and models, ensuring that the replacement is done correctly.

2. Proper Tools and Equipment

Drive belt replacement often requires specialized tools, such as belt tensioners and pulley holders. Professional auto repair shops are equipped with the necessary tools to perform the job efficiently and safely.

3. Warranty and Guarantees

Many professional auto repair shops offer warranties or guarantees on their work. This provides peace of mind knowing that if any issues arise after the replacement, they will be addressed at no additional cost.

4. Comprehensive Inspection

A professional drive belt replacement service often includes a comprehensive inspection of the vehicle’s other components, such as the pulleys, tensioners, and engine. This can help identify potential issues before they become major problems.

DIY Drive Belt Replacement: Pros and Cons

Pros

- Cost Savings

One of the main advantages of DIY drive belt replacement is the potential cost savings. By doing the job yourself, you can avoid labor costs associated with professional services. - Learning Experience

Replacing a drive belt can be a valuable learning experience, helping you better understand your vehicle’s mechanics and how to perform basic maintenance tasks. - Convenience

If you have the necessary tools and a good understanding of the process, you can replace the drive belt at your convenience, without having to schedule an appointment or wait at a repair shop.

Cons

- Risk of Incorrect Installation

Without the proper knowledge and experience, there is a risk of incorrectly installing the drive belt. This can lead to further damage to the engine or other components. - Lack of Specialized Tools

Drive belt replacement often requires specialized tools that may not be readily available to the average DIYer. Attempting to replace the belt without these tools can make the job more difficult and increase the risk of errors. - No Warranty or Guarantee

Unlike professional services, DIY repairs do not come with a warranty or guarantee. If something goes wrong, you will be responsible for any additional repairs or costs. - Time-Consuming

For those unfamiliar with the process, drive belt replacement can be time-consuming. It may take several hours to complete the job, especially if you encounter any difficulties.

How Often Should Drive Belts Be Replaced?

The frequency of drive belt replacement depends on several factors, including the type of belt, the vehicle’s make and model, and driving conditions. Here are some general guidelines:

1. Serpentine Belts

Serpentine belts typically last between 60,000 to 100,000 miles. However, it’s essential to refer to the vehicle’s owner’s manual for specific recommendations. Regular inspections can help identify signs of wear and determine when replacement is necessary.

2. V-Belts

V-belts generally have a shorter lifespan compared to serpentine belts, often needing replacement every 30,000 to 50,000 miles. Again, consult the owner’s manual for specific guidelines.

3. Timing Belts

Timing belts usually need replacement every 60,000 to 100,000 miles, depending on the vehicle. Some manufacturers recommend replacement based on time (e.g., every 5-7 years) rather than mileage. Failure to replace a timing belt on time can result in severe engine damage.

Cost of Drive Belt Replacement

The cost of drive belt replacement varies depending on the type of belt, the vehicle’s make and model, and whether you choose a professional service or DIY approach. Here are some general cost estimates:

1. Serpentine Belt Replacement

- Professional Service: 100to200 (including parts and labor)

- DIY: 20to50 (for the belt only)

2. V-Belt Replacement

- Professional Service: 50to150 (including parts and labor)

- DIY: 10to30 (for the belt only)

3. Timing Belt Replacement

- Professional Service: 300to800 (including parts and labor)

- DIY: 50to200 (for the belt and related components)

Keep in mind that these are general estimates, and actual costs may vary based on your location, the specific vehicle, and the repair shop’s rates.

Conclusion

Drive belt replacement is a critical maintenance task that ensures the smooth operation of your vehicle’s engine and various systems. Regular inspections and timely replacement can prevent costly repairs and keep your vehicle running efficiently. Whether you choose a professional service or opt for a DIY approach, understanding the process and importance of drive belt replacement is essential for every vehicle owner.

By following the guidelines outlined in this guide, you can make informed decisions about your vehicle’s maintenance and ensure that your drive belts are in optimal condition. Remember, when in doubt, it’s always best to consult with a professional technician to ensure the job is done correctly and safely.