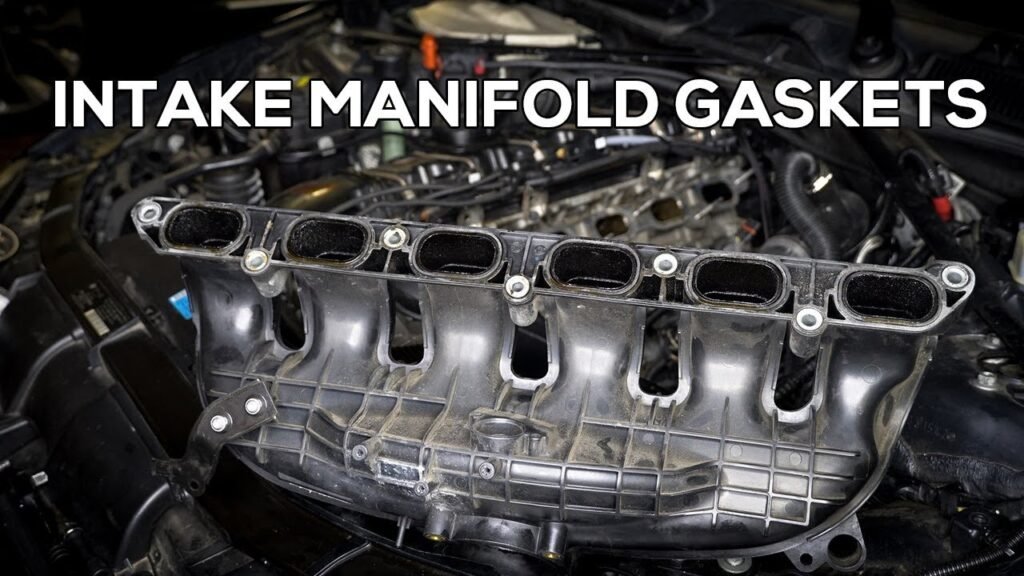

Replacing an intake manifold gasket is a common repair for engine leaks, overheating, or performance issues caused by a failing gasket. Below is a step-by-step guide to help you through the process.

Tools & Materials Needed:

-

New intake manifold gasket (ensure correct part for your engine)

-

Socket set & wrenches

-

Screwdrivers (flathead & Phillips)

-

Torque wrench

-

Gasket scraper or razor blade

-

Shop rags & brake cleaner (for cleaning surfaces)

-

RTV silicone (if required by manufacturer)

-

Pliers (for hose clamps)

-

Funnel & coolant (if coolant passages are involved)

-

Torque specs (check service manual)

Step-by-Step Replacement Guide

1. Safety Precautions

-

Disconnect the negative battery terminal.

-

Allow the engine to cool if it was running.

-

Drain coolant (if the intake manifold has coolant passages).

2. Remove Components Blocking Access

-

Remove the air intake assembly (air filter, MAF sensor, etc.).

-

Disconnect throttle body cables/hoses (if applicable).

-

Unplug electrical connectors (sensors, fuel injectors, etc.).

-

Label hoses and wires for easier reassembly.

3. Remove Fuel System Components (if needed)

-

Relieve fuel pressure (if required).

-

Disconnect fuel lines and fuel rail (some engines require this).

4. Remove Intake Manifold Bolts

-

Loosen bolts in the reverse order of the torque sequence (usually outside-in).

-

Keep track of bolt locations (some may be different lengths).

5. Lift Off Intake Manifold

-

Carefully pry the manifold loose if stuck (avoid damaging surfaces).

-

Check for warping or cracks on the manifold (resurface if needed).

6. Clean Gasket Surfaces

-

Remove old gasket material from the cylinder head and manifold.

-

Use a gasket scraper or plastic razor blade (avoid scratching aluminum).

-

Clean surfaces with brake cleaner and a rag.

7. Install New Gasket

-

Place the new gasket dry (unless specified otherwise by manufacturer).

-

Some engines require RTV silicone at corners (check manual).

-

Ensure proper alignment (some gaskets are directional).

8. Reinstall Intake Manifold

-

Carefully lower the manifold onto the gasket.

-

Hand-tighten bolts in the correct torque sequence (usually inside-out).

-

Torque bolts in stages to the specified value (prevents warping).

9. Reconnect All Components

-

Reattach fuel system, hoses, wiring, and sensors.

-

Refill coolant (if drained) and bleed air from the system.

-

Reconnect the battery.

10. Test for Leaks

-

Start the engine and check for vacuum leaks (hissing sound).

-

Inspect for coolant or oil leaks.

-

Verify proper idle and performance.

Common Symptoms of a Bad Intake Manifold Gasket:

-

Rough idle or stalling

-

Coolant/oil leaks near the manifold

-

Engine misfires (due to vacuum leaks)

-

Overheating (if coolant passages are compromised)

-

Check Engine Light (codes like P0171/P0174 for lean mixture)

Tips:

✔ Always use a torque wrench—over-tightening can warp the manifold.

✔ Replace other gaskets (throttle body, EGR) while you’re in there.

✔ If the engine has a plastic manifold, be extra gentle to avoid cracks.

If you’re unsure about any step, consult a service manual for your specific engine. Let me know if you need torque specs or diagrams for your vehicle!

Would you like help diagnosing whether your gasket is actually bad?